The US Shift Wiring Harness System

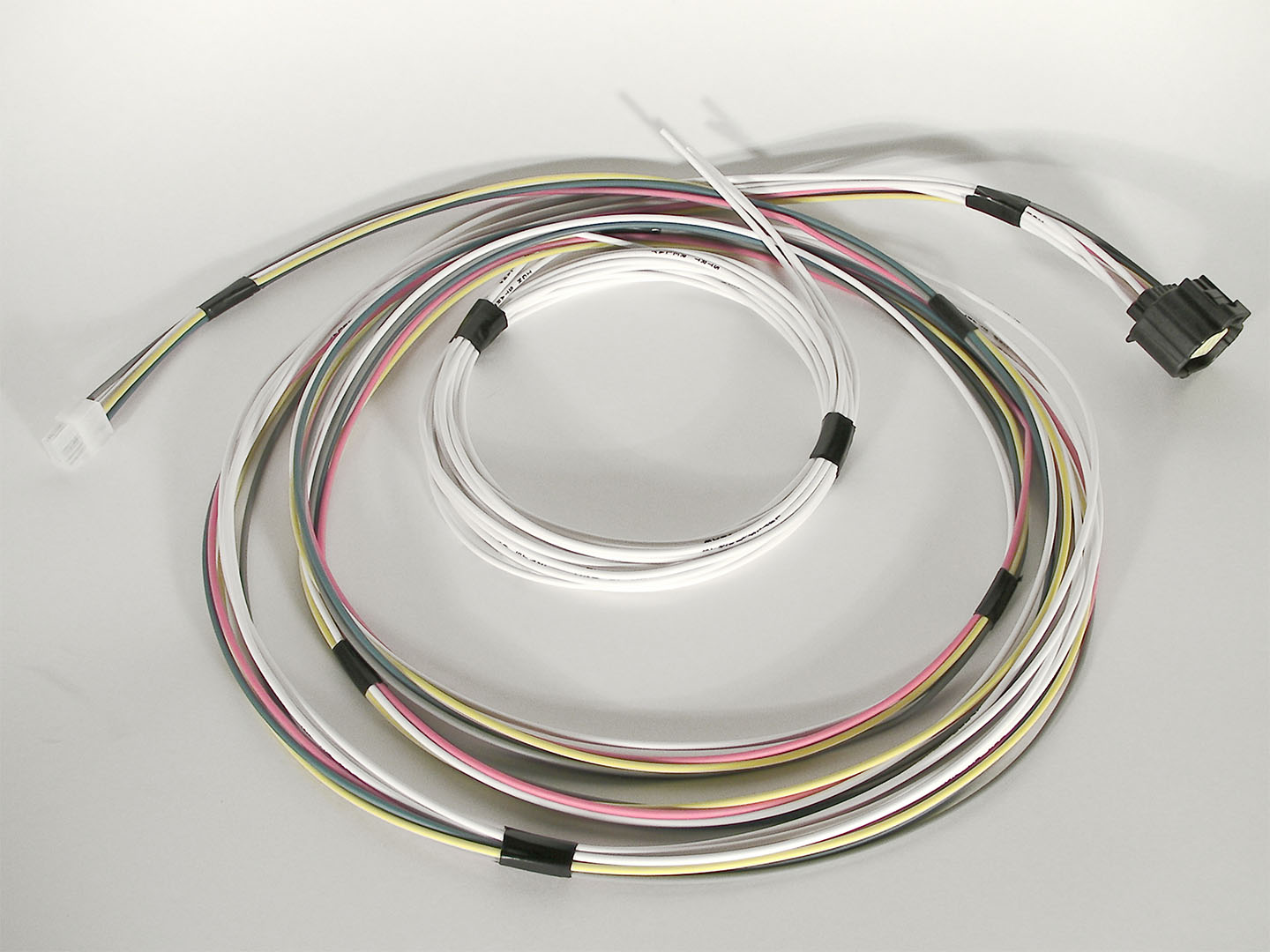

US Shift controllers utilize a modular wiring harness construction that is unique within the industry. This approach provides several benefits to our customers, including reduced cost, quick shipment, and ease of customization. With this new and innovative approach, we can tailor our wiring harnesses to your specific application for little or no additional cost or time.

Another benefit to our modular harness design is that upgrading an existing installation is simple because all harnesses from our second generation and up controllers are compatible, so upgrading is as simple as plugging in. In some cases, a new lead may need to be added to an existing install which would be as simple as inserting an included wire into the connector shell.

Once you determine your desired routing for the harness and the "break-outs" (forks) that you need, you can then cover it with slit loom or your covering of choice. We can provide a high-temperature slit loom covering kit for only $10.

Another benefit of this system is that it allows us to easily accommodate needs that aren't met by our standard harness packages. For instance, if you are using a different range sensor (PRNDL switch) or speed sensor than your transmission would normally be equipped with, we can fulfill that request with no shipment delay. We can also provide a harness with only some of the OEM connectors at a cost savings for applications where it makes sense to reuse some of the original connectors.

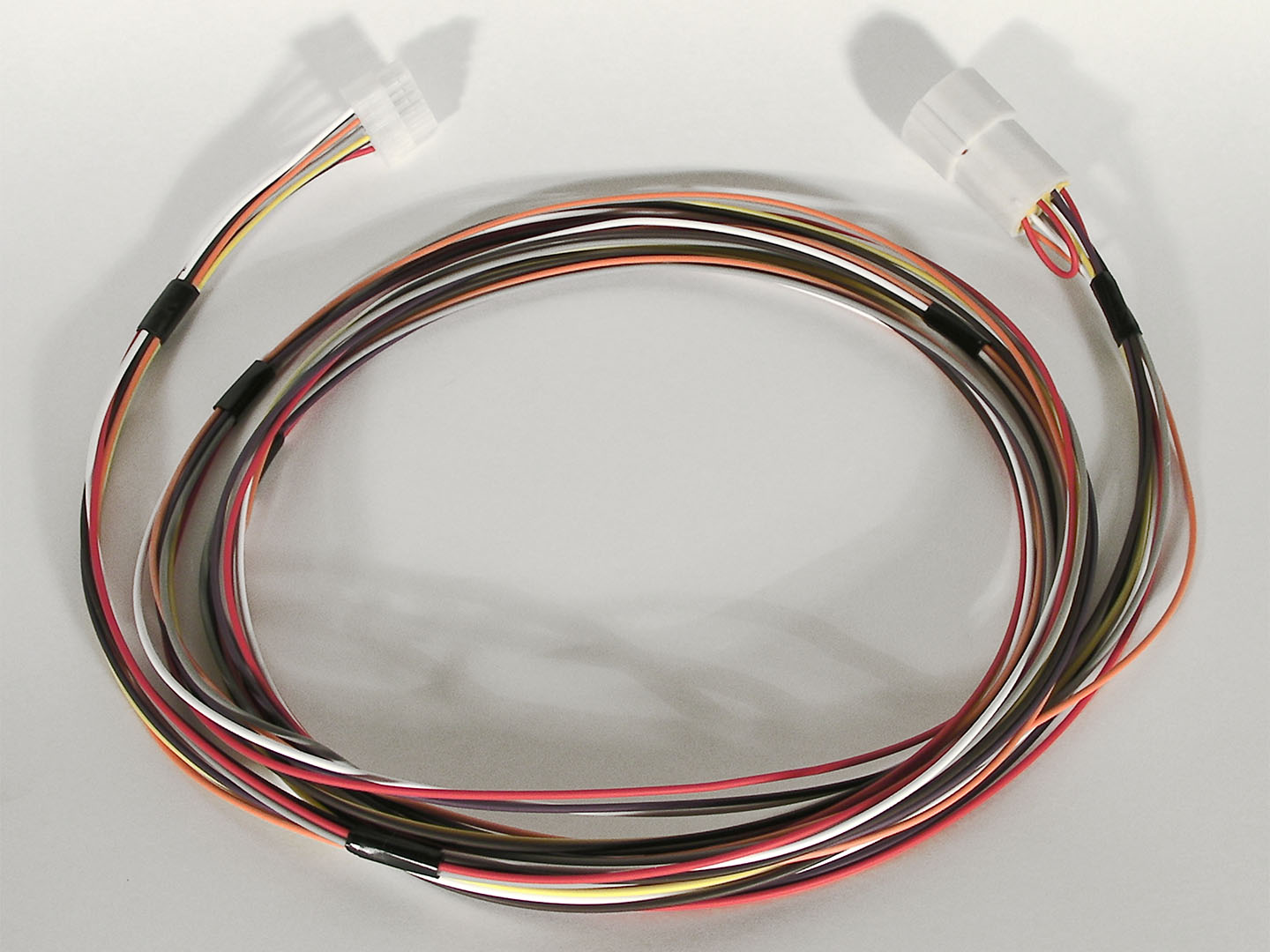

Our transmission solenoid harnesses come in standard lengths of 8-9 feet (depending upon application, with most speed sensor harness sections being longer). If your project would benefit from a shorter harness, then we can provide shorter versions of our harnesses for no extra cost, and with minimal shipping delays. Please note, however, that custom length harnesses are not returnable. It is also possible to extend our harnesses beyond their standard length, or to provide extension harnesses. Lengthened harnesses will cost more, and will take longer to produce, so please contact us for details.

Since our modular harnesses use three separate, smaller connectors to route signals to the transmission, wiring can be accomplished without cutting large holes in your favorite sheet metal. A 1-1/8" round or 1-1/8" x 5/8" rectangular opening is large enough for all of the transmission harness connectors to pass through into the passenger compartment. With an optional connector pin removal tool (catalog number PRT1), it is easy to remove the pins from some or all of the connector shells, then snap them back in after routing the harness through the hole. With this method, it is possible to route the transmission wiring through a hole as small as 1/2". Connector pin-out illustrations are provided to help insure correct reassembly of the connectors.

The modular harness concept also greatly simplifies system troubleshooting. Since all wiring runs from point-to-point without any internal splices or connections, it is very easy to verify wire routing and make measurements with a meter. The connectors on the controller are also very easy to inspect and probe, should you ever need to.