US Shift Quick 6 Gen2 Clutch-to-Clutch Transmission Control System

with Integrated OLED Graphical Display

Featuring REVolution Architecture

Currently Supporting 2011+ Ford 6R80 Transmissions

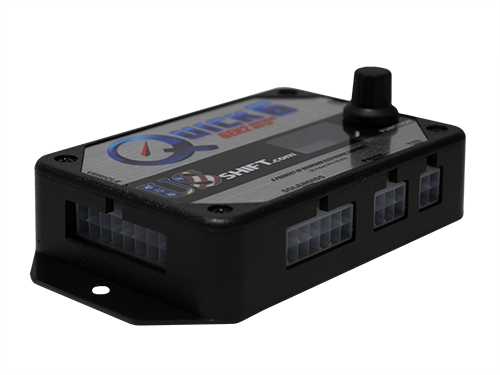

The Quick 6 is a powerful, fully-featured, and easy-to-use transmission controller based on REVolution architecture. It enables the use of an electronic 6R80 transmission on a wide variety of vehicles that lack the OEM capability, such as classic cars, trucks, or motorhomes. It can also be used to enhance a modern vehicle's performance by taking over control from the OEM computer, allowing the user to directly adjust shift points, firmness, torque convter engangement, and much more.

Featuring...

- Graphical user interface enables easy adjustment to most settings without the need to connect a PC

- Redisigned PCB from the ground up

- Featuring pre-loaded data, no longer requiring a clutch learning procedure

- Simplified setup allows you to install and drive immediately

- Shift quality improvements result in consistent, excellent, OEM-quality shift feel

- Compatible with aftermarket torque converters.

Gen2: A New Shift in Design

Introducing the all-new Gen2 Quick 6 transmission controller from US Shift. When we set out to redesign the Quick lineup, we didn't just want to give it a simple iterative refresh. We went back to the drawing board for a complete overhaul and the resulting new design has improved each controller's functionality, ease of use, power efficiency, diagnostic abilities, and more.

Display

The new feature that stands out the most on the Gen2 is our new OLED user interface display. It lights up bright enough to be seen in daylight and retains excellent contrast. The OLED display also features a wide viewing angle, making it ideal for mounting below or to the side of the driver position without suffering wash-out. It has a much wider temperature range than standard LCD displays, meaning it will continue to function whether you're over-landing in the sweltering heat of Moab or the frigid tundras of Alaska.

(Note: The color of the display depends on availability and is subject to change. Currently, we are using white displays.)

User Interface

Using the Gen2's new UI is a breeze. The home screen gives you real-time info on things like PRNDL position, currently-commanded gear, speed, configuration table in use, and any fault codes that may appear. To access the main menu, simply turn the knob and it will immediately appear. All of the menus and functions have been carefully crafted to be easily understood and adjusted. Most of the adjustments that can be made using a computer with our Shiftware software can also be done from the built-in user interface. Examples include adjusting shift timing, shift firmness, torque converter clutch engagement, switching calibration tables, and adjusting the speed sensor settings, just to name a few.

Diagnostics

The Gen2 features comprehensive diagnostic tools. Each individual solenoid output is precisely monitored and error messages are more specific, taking you directly to the problem. And advanced diagnostics data can be accessed directly through the UI's menu instead of having to connect the controller to a PC. These improvements makes installation and troubleshooting easier than ever before.

Design

The newly redesigned Gen2 controllers feature a new circuit board which is more power efficient and runs cooler thanks to advanced thermal management, improving reliability. Additional protection circuitry prevents controller damage which could be caused by accidental mis-wiring. We've also added a robust, high-temperature-rated EEPROM IC with error correction for storing critical data - such as tunes, settings, and learned data - which has been rated to maintain data integrity for at least 200 years. Firmware is stored in newly-enhanced flash memory with error correction code technology. And, as with our past controllers, constant power is not needed to maintain saved data, meaning power loss doesn't erase your settings and your battery won't be drained during long periods of storage.

Further PCB Improvements Include...

- Elimination of configuration jumpers. Now, functions that previously required a jumper change are changed automatically in software for easy setup.

- New outputs have been added which can be customized by the end user.

- Elimination of the external capacitor needed for the speedometer signal output.

- Improved engine RPM signal input which improves compatibility with different engine RPM signals, such as direct ignition coil connections in HEI, TFI, and breaker point ignition systems.

Common source vehicles are 2011 and newer Mustang GTs and Ford F150s (equipped with the 5.0L V8). A 6R80 can be swapped into a wide variety of vehicles, such as the Fox body Mustang. With a growing ecosystem of swap parts becoming available, it's easier than ever to adapt a 6R80 into the vehicle of your choice. More transmissions will be supported in the future, such as the new GM and Ford 10 speed units. Other clutch-to-clutch transmissions under consideration are the GM 6L80, GM 8L90, Ford 6R140, and possibly the Ford 5R110. We will select our next transmission applications based upon customer demand, so please contact us if you are interested in a particular transmission application.

Quick 6 further builds on the advanced REVolution firmware architecture of Quick 4 to deliver the most advanced stand-alone clutch-to-clutch transmission controller in the industry. It utilizes a unique self-tuning process (protected by US patent #10,100,922) that greatly simplifies setup and tuning, while maximizing adaptability to many different applications, vehicles, and power levels. The self-tuning capability and refined adjustment process enables an installation, setup, and tuning experience that is comparable to, or even easier than, a four speed transmission such as a 4L80E or 4R70W.

The Quick 6 has unparalleled shift quality with the ability to perform smooth light-throttle shifts and quick full-throttle shifts. Quick 6 provides shift quality customization capabilities that surpass what has previously been possible in the industry. If the low first gear utilized in most 6-10 speed transmissions is not suitable for your application, it is possible to start in second gear, which will effectively create a close ratio 5 (or more) speed transmission.

The shift algorithms (protected by US patent #10,100,922) are intrinsically safe, offering integrated protection against tie-up due to tuning errors or other issues. Extensive self-monitoring and diagnostic capabilities provide an additional margin of safety and will invoke fail-safe mode if a potentially unsafe condition is detected. Exclusive Power-On Solenoid Check (POSC) provides a full test of all solenoids at power-ups as an enhancement to self-monitoring and as a valuable aid to diagnostic troubleshooting.

Along with all of the capabilities of the Quick 6, it also has a long list of features carried over from the Quick 4, such as...

- Advanced algorithms provide the highest level of shift control and synchronization, allowing you to maximize the performance of your combination.

- The most advanced torque converter clutch control available, with several actions available during shifts.

- Accushift ™ learning capability for the most accurate WOT shift points possible.

- Adjustable throttle lift delay, overdrive shift delay, and ballistic throttle effect.

- Burnout mode prevents upshifts while "pedaling" the throttle.

- Up to 4 pre-loaded shift calibrations able to be selected on the fly.

- FLEX-SHIFT ™ Shifter re-mapping capability with enhancements for modern transmissions.

- Metric Support.

- Transmission slip detection.

- 100Hz high-resolution data logging of all vital parameters and viewable in a graphic interface.

- Dedicated 4wd options and features.

- Compact size gives you the freedom to install in tight areas (4.165 x 2.8 x 1.1 inches)

- And many more cutting-edge features seen here.

US Shift Transmission Control System protected by US Patents #10,100,922 & #10,767,759.

Quick 6 System with 6R80 Wiring Harness: $1255

Do you own a previous generation Quick 6 controller with wiring already installed? You can contact us if you'd like to exchange your previous controller for a new one. We'll go over all the details specific to your build over phone or email.

Already own a Quick 6? Learn about having your firmware updated to take advantage of new features.

Additional Prices

Wiring Information

Why Should You Choose US Shift?

California Residents Only - WARNING: Prop65 Info

Online Purchasing

Choose your transmission below to begin the kit builder wizard, which will help you choose the correct kit to purchase for your vehicle.

Ford 6R80

If you'd rather order by phone or email, feel free to contact us.

Quick 6 Installation Manual

We believe that the more you know about US Shift products, the more you will like them, so we encourage you to download and inspect our manuals and tuning software before you buy our products. Feel free to contact us with any questions you may have.

Ford 6R80 Quick 6 Installation Manual

This manual describes the installation, tuning, and operation of the Quick 6 for the Ford 6R80 transmission.

Check out our SEMA show brochure.

Learn more about the 6R80 transmission's features, benefits, and vehicles it can be swapped into.

Transmission Controller Feature Comparison

| Product | Quick2 | Quick4 | Quick6 |

|---|---|---|---|

| Supported Transmissions | 4L60E, 4L65E, 4L70E, 4L80E, 4L85E, 4R70W, 4R75E, E4OD, 4R100 | 6R80 (more to come) |

|

| Calibration Tables (Tunes) | 1 | 4 | 4 |

| Manutronic Push-Button / Paddle / H-Gate Shifting |

|

|

|

| Ratio-Corrected Speedo Signal Output |  |

|

|

| FLEX-SHIFT |  |

|

|

| TCC Control | Basic Cruise-Mode Operation | Full-Range Control with WOT Capability & Programmable Shift Action | |

| Performance Ballistic Shift Control & Throttle Release Delay |  |

|

|

| Top Gear Delay |  |

|

|

| Input Shaft Speed Sensor (where available) |  |

|

|

| Engine RPM Input (more accurate shift points & slip detection |  |

|

|

| OFF-RODE TCC Control (enhanced performance & engine braking in manual ranges) |  |

|

|

| Burnout / Drag Race Mode |  |

|

|

| 4x4-LO Transfer Case Ratio Compensation | Manual (using controller display) | Automatic or Manual | |

| Multiple Low-Range Capability (for crawler box) |

|

|

|

| Adjustable Overheat Alarm |  |

|

|

| Reverse Throttle Position Sensor Capability |  |

|

|

| 100Hz Data Logging (with graphical viewer) |  |

|

|

| Optional CAN Bus Data Interface |  |

Coming Soon | Coming Soon |

| Integrated Trans-Brake |  |

|

Quick6 Pro Only |

| 10 Year Warranty |  |

|

|

How the Quick 6 Easy Setup and Self-Tuning Work for You

Until now, setting up and tuning a clutch-to-clutch transmission has been a very time consuming and difficult process. This is due to the fact that, unlike earlier electronic transmissions, the valve bodies in these modern transmission designs no longer internally manage clutch apply rates and the timing of shift events. These new-generation valve bodies mainly consist of a set of pressure regulator solenoids that directly control the hydraulic pressure applied to each clutch. During a shift, the pressures of the on-coming and off-going clutches must be controlled and synchronized by the transmission controller in real time.

This is a stark contrast to earlier four-speed designs, where the transmission controller commanded a shift by simply turning a solenoid on or off, leaving the coordination of on-coming and off-going clutch pressures, as well as clutch apply rates (shift feel) to a series of valves, springs, orifices, and accumulators in the valve body. Since it's impractical to implement complex functions with hydraulic valves, the shift timing and shift feel control of earlier transmissions always involved compromises. Shifts were often either too soft or too firm, while clutch apply and release timing during shifts often erred on the side of overlap (dragging the off-going clutch or band excessively as the on-going clutch was applied). The simple nature of hydraulic valving meant that a perfectly timed shift event was more a matter of luck than precision, making it very difficult to properly compensate for changes in engine power, friction materials, etc. These compromises usually led to diminished performance or reduced transmission longevity, and as more speeds were added, this familiar method became increasingly impractical, necessitating a new approach.

The move to real-time control of clutch pressures has placed intense new demands on transmission controllers, while dramatically increasing the complexity of their tuning. The up-side of this change is that new levels of shift quality, performance, and transmission durability are now possible. Unfortunately, the increased tuning complexity and consequences of tuning mistakes rendered this new technology unapproachable to all but the most hard-core tuners, at least until now. In order to create a practical, safe, and easy-to-use system, we knew that a simple, automated tuning method was mandatory. We felt that a clutch-to-clutch transmission controller would be of no value to the performance and racing market if it required special training, hours of data analysis, and adjustment of hundreds of data points in order to work properly. Releasing such a product had the potential to frustrate customers and would not improve our image as a company.

Because of this, we avoided the temptation to rush a clutch-to-clutch transmission controller to market and instead focused on building an intelligent system that would finally enable enthusiasts and builders to install these great new transmissions in any vehicle. The selection of a very capable and powerful micro-controller architecture made such an intelligent system possible. Months of research, experiments, and countless hours of data log analysis followed, all aimed at gaining a solid understanding of the requirements for ideal automated clutch-to-clutch transmission tuning. Once the process was well understood, we manually tested various algorithm ideas, coding them once success was achieved.

The automated process ended up being so effective and unique that we decided to file our first patent to protect our investment in this technology, allowing us to reveal more of its inner workings to customers. (Protected by US patent #10,100,922) Had we elected to hide this technology as a "trade secret", it would have forced us to suppress a lot of vital information from data logs and customer documentation. We felt that suppressing important details and data would complicate troubleshooting and limit our customer's understanding of the system. So we opted to forgo the "black box" option, instead pursuing a more open approach with patent protection.

The automatic tuning process is straightforward and involves minimum effort. The Quick 6 comes pre-loaded with a default calibration and learned clutch data. Once installation is complete, the throttle positions have been calibrated, and the transmission is warm, the controller is ready for dynamic learning. The vehcile is first driven at light throttle, then with increasingly more throttle to perform dynamic learning. As the vehicle is driven, shift quality will steadily improve as the controller learns more and refines the calibration. For best results, the vehicle should be driven until the transmission reaches full operating temperature and shift quality is ideal. After learning, additional adjustments can be made to shift firmness, if desired.

Learned clutch data is used to determine the pressures at which each clutch begins to engage and release, as well as the time that it takes them to apply and release, and is used as a baseline. Dynamic learning is primarily a monitoring process, similar to analyzing data logs after a drive, and then making adjustments based on the data. As each shift is performed, it is analyzed in real-time. Once the shift is completed, the actual data is compared to the expected performance and adjustments are made, as needed. Adjustments are made to on-going clutch pressure to match the needs of engine torque at each load point, while off-going clutch pressure is adjusted to provide adequate holding pressure without flare or bind during the shift. This process essentially creates a custom tune tailored to the exact vehicle, engine, and transmission combination, while automatically accounting for all modifications and variations within. The learned data is permanently stored in flash memory and will not be lost if the battery is disconnected or goes dead.

With this enabling technology, these durable, modern transmissions can finally become the clear choice for most builds, enabling performance levels that were previously unimaginable. Many of these new transmissions, such as the Ford 6R80, are far superior to earlier options and present exciting, revolutionary potential for power handling and performance.