Why Should You Install a Ten-Speed Transmission

Into Your Vehicle Build?

Our fellow car nuts might be wondering whether the 10 speed Ford and GM transmissions are worth the effort. When you drive a late-model vehicle that already has one, it can be difficult to tell how much of the performance can be attributed to the transmission versus the engine. In the OEM 10-speed vehicles, you experience the whole package, rather than the individual pieces. When installing one of these transmissions in an earlier vehicle, especially when replacing a four-speed unit, it quickly becomes obvious that the juice is worth the squeeze. The effect is not only similar to a small power adder, but it also elevates the driving experience, increasing enjoyment, while also enhancing comfort and economy. It is not an overstatement to say that these transmissions transform the driving experience and enjoyment of a vehicle.

Optimized and Versatile Gearing

The gear ratios in these transmissions are extremely close (much closer than typical 3, 4, 5, and 6-speed automatic transmissions). This allows the engine to operate within about 1000 RPM (or less) at WOT. (Please see the chart below comparing estimated WOT RPM ranges for different transmissions.) Therefore, the engine is always operating near peak power. Because of this, the average power delivered by the engine during WOT acceleration is significantly higher, and very close to the engine's peak horsepower. With older transmissions, the average power at WOT will be significantly lower. In this respect, ten-speed transmissions act as a power adder, similar to low boost supercharging or a small nitrous system, without the potential complications and reliability issues of these systems. The close ratios are a great fit for any application and will especially maximize naturally aspirated engines with long duration camshafts.

Gear ratio comparison based on 6000 RPM WOT shift points.

Torque converter slip at shift point = 200 RPM (estimated)

Torque converter slip after shift = 600 (estimated)

* Utilizing Sync Release

| GEAR RATIO COMPARISON | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RPM After W.O.T. Shift | ||||||||||||||

| Transmission | 4L80E TH400 C4 |

4L60E TH700R4 |

4R70W | C6 | 6R80* | 10R80* 10L90* |

||||||||

| Gear | Gear Ratio | RPM | Shift | RPM | Shift | RPM | Shift | RPM | Shift | RPM | Shift | RPM | Shift | |

| 10R80 10L90 |

1st | 4.696 | ||||||||||||

| 6R80 | 1st | 4.17 | ||||||||||||

| 4L60E TH700R4 |

1st | 3.06 | ||||||||||||

| 10R80 10L90 |

2nd | 2.985 | 4414 | 1-2 * | ||||||||||

| 4R70W | 1st | 2.84 | ||||||||||||

| 4L80E TH400 C4 |

1st | 2.48 | ||||||||||||

| C6 | 1st | 2.46 | ||||||||||||

| 6R80 | 2nd | 2.34 | 3967 | 1-2 | ||||||||||

| 10R80 10L90 |

3rd | 2.156 | 4934 | 2-3 * | ||||||||||

| 10R80 10L90 |

4th | 1.779 | 5551 | 3-4 * | ||||||||||

| 4L60E TH700R4 |

2nd | 1.63 | 3690 | 1-2 | ||||||||||

| 4R70W | 2nd | 1.55 | 3765 | 1-2 | ||||||||||

| 10R80 10L90 |

5th | 1.526 | 5747 | 4-5 * | ||||||||||

| 6R80 | 3rd | 1.52 | 4497 | 2-3 | ||||||||||

| 4L80E TH400 C4 |

2nd | 1.48 | 4061 | 1-2 | ||||||||||

| C6 | 2nd | 1.46 | 4042 | 1-2 | ||||||||||

| 10R80 10L90 |

6th | 1.278 | 5625 | 5-6 * | ||||||||||

| 6R80 | 4th | 1.14 | 5100 | 3-4 | ||||||||||

| 4L80E TH400 C4 |

3rd | 1.00 | 4519 | 2-3 | ||||||||||

| 4L60E TH700R4 |

3rd | 1.00 | 4158 | 2-3 | ||||||||||

| 4R70W | 3rd | 1.00 | 4519 | 2-3 | ||||||||||

| C6 | 3rd | 1.00 | 4573 | 2-3 | ||||||||||

| 10R80 10L90 |

7th | 1.00 | 5295 | 6-7 * | ||||||||||

| 6R80 | 5th | 0.87 | 5179 | 4-5 | ||||||||||

| 10R80 10L90 |

8th | 0.854 | 5724 | 7-8 * | ||||||||||

| 4L80E | 4th | 0.75 | 4950 | 3-4 | ||||||||||

| 4L60E TH700R4 |

4th | 0.70 | 4660 | 3-4 | ||||||||||

| 4R70W | 4th | 0.70 | 4660 | 3-4 | ||||||||||

| 6R80 | 6th | 0.69 | 5359 | 5-6 | ||||||||||

| 10R80 10L90 |

9th | 0.689 | 5441 | 8-9 * | ||||||||||

| 10R80 10L90 |

10th | 0.636 | 5538 | 9-10 | ||||||||||

At part throttle, the close ratios also maximize productivity of the engine, allowing you to accelerate quickly with minimal throttle input. As a result, everything just feels better across the board, leading to more enjoyment, better drivability and improved fuel economy. The close ratios also minimize RPM drop during each shift, leading to better shift quality with quick, seamless shifts.

With 10 distinct forward gear ratios, another advantage of the 10-speed transmissions is their "ratio spread" or the difference between the lowest and highest gear ratios (lowest ratio divided by the highest ratio). For the 10L80 and 10R80, this value is 7.38, while it is less than 2.5 for most three-speed automatics, and about 4 for most 4-speeds. This large ratio spread permits blistering launch performance, with low-RPM high-speed cruising for minimal noise, engine wear, and fuel consumption.

The first gear ratio in these transmissions is 4.696:1, which has a dramatic effect on rear axle gearing requirements (see the Unity Motorsports YouTube video below discussing "launch ratio"). Launch ratio is the effective gear ratio in first gear and is equal to the first gear ratio multiplied by the axle ratio. For example, a 4L80E transmission with a 4.56 axle ratio would have a launch ratio of 2.48 x 4.56, or 11.31, while a 10L80 with a 2.73 axle ratio would result in a ratio of 4.696 x 2.73, or 12.82, putting more torque to the tires.

As you can see, many vehicles will work perfectly with axle ratios in the 2.73-3.27:1 range. Vehicles with excellent traction may be able to utilize ratios between 3.55 and 4.10:1. Vehicles with lower axle ratios, such as 4.30 and 4.56:1 will probably need to utilize the second gear start option. Obviously, driveshaft torque will be much higher, so stronger U-joints, yokes, etc. are important. However, using these taller axle ratios will significantly reduce driveshaft speed, reducing the risk of reaching the critical speed of the driveshaft assembly. If you are building a vehicle from scratch, it is likely that you will already have a suitable ring and pinion in your original rear axle.

In the previously mentioned video, Andy Wood makes reference to all of the custom gear ratios available for the TH400, which enable drag racers to precisely dial-in the launch ratio and the RPM drop during the 1-2 shift. With the variety of ratios in the 10-speed transmissions, a similar effect can be achieved, while retaining overdrive ratios that are beneficial for street-strip applications.

Certain vehicles will not be able to utilize first gear, due to minimal traction, excessive torque, low (high numerical) axle ratios, etc., but there is an advantage to this. The 1-2 shift is the largest ratio step in these transmissions, so the transmission becomes a super-close-ratio transmission when utilizing our second or third gear start options. In four-wheel-drive applications where first gear is not useful on the street, it can be utilized only in low range to enhance the vehicle's crawl ratio.

Vehicles with long-duration camshafts (necessitating higher cruising RPM) may not be able to utilize tenth (or ninth) gear at cruising speeds. In these cases, these shifts can be disabled or delayed until much higher speeds. Even if some gears are disabled, these transmissions will still allow for at least 6 gears to be used in a typical 1/4-mile dragstrip pass. This maximizes power utilization by keeping the engine in a very narrow RPM range throughout the pass.

Other Beneficial Features and Characteristics

These transmissions are also very strong, being rated for about 600 ft-lb of torque in factory applications. In stock form, they can handle engines producing up to 700 HP. Aftermarket support is excellent, and there are plenty of upgrades available to support four-digit power levels.

Downshifts are another area where the 10-speed transmissions shine. Any downshift can be executed in one or two steps, and downshifts to any gear from seventh gear or below can be executed in a single step. In performance driving situations, the three overdrive ratios (8, 9 and 10) will generally not be needed, so we are adding an “overdrive disable” mode to Quick 10, allowing all downshifts to occur in a single step. Having immediate access to any lower gear from the present gear dramatically improves the responsiveness of the transmission. We have also worked hard to optimize our downshift selection algorithm, so that the transmission will instantly jump to the correct gear when you command a downshift via the accelerator pedal.

For superior launches, our Quick 10 controller includes an integrated trans brake feature at no extra cost. No modifications to the transmission are necessary to enable this option, and only an activation button is required to make it work. The trans brake feature is functional for first, second and third gear starts, maximizing versatility.

Minimal Torque Loss and Maximum Power Transfer

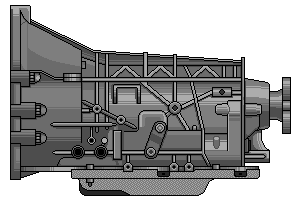

While the close gear ratios do their part to maximize power utilization and efficiency, the 10-speed transmissions have several features that reduce parasitic losses. First, the geartrain uses needle bearings in conjunction with the ultra-low viscosity fluid to minimize friction. Secondly, out of the six clutches in the transmission, four are always applied in each gear. Unapplied clutches will cause drag, wasting power and fuel. Since only two clutches are unapplied at any time, losses from clutch drag are minimized. Spacers are also installed between the clutch plates to further reduce drag when a clutch is not applied.

Also, like the 6R80 and 6L80E before them, the 10R and 10L transmissions use balance pistons in the rotating clutches. At high RPM, centrifugal force will push the residual fluid behind an unapplied clutch piston to the outer circumference of the piston, where it will accumulate and begin to stroke the apply piston. It will not generate enough force to fully apply the clutch, but it will tighten up the clutch clearances and increase clutch drag. This drag will consume engine torque rather than transmitting it to the wheels, where it belongs. It can also generate heat and potentially burn the friction plates. The balance piston holds residual fluid on the opposite side of the clutch apply piston, where centrifugal force can also act upon it, counteracting the centrifugal force that is trying to apply the clutch. As a result, the apply piston remains in the bottom of the bore in the fully released position, preventing clutch drag at high RPM. This feature is especially vital with cutting-edge engines that operate at high RPM.

Finally, the 10L and 10R transmissions utilize an off-axis variable displacement fluid pump. This gear driven pump is mounted adjacent to the valve body, near the bottom of the fluid pan. This allows the pump to prime quickly and deliver fluid more efficiently. Instead of dumping excess capacity to the sump to regulate line pressure, pump displacement is reduced to eliminate excess pressure. When pump capacity is reduced, torque input to the pump is reduced proportionally. The reduced torque requirements improve efficiency, reduce heat generation, and most importantly, leave more torque available to send to the tires.

Reliability and Updates

Like any other totally new automatic transmission platform, we cannot deny that the 10-speed units experienced some growing pains in their first few years. Despite the best efforts of design, analysis and testing, updates are usually made to new transmissions after the first few model years. These units are no exception, but it is important to note that even the first few model years of 10-speeds can still last for 100,000 miles or more in average service. Therefore, a low-mileage 2018 unit is still a great option for a moderate build that sees weekend duty. High-powered applications will likely need durability upgrades (improved clutches, etc.), and the internal updates can be performed at that time.

It is also worth noting that since both Ford and GM are using these transmissions, they had to pass the engineering scrutiny and testing procedures of both companies. It is likely that these transmissions were subjected to more rigorous qualification criteria than any other transmission designed by the Big 3 automakers. It’s fair to say that these transmissions are the culmination of over 70 years of lessons learned and acquired knowledge of the two largest US automakers.

Those old enough to remember the launch of the Ford E4OD and GM 700-R4 may recall that the first few years of those transmissions were not perfect. Both evolved into solid units after several model years, with the 700-R4 becoming the 4L60, then the 4L60E, 4L70E, etc., and the E4OD becoming the 4R100. Despite the initial challenges, both grew into well-respected transmissions. This is where we are with the 10R80 and 10L80 transmissions after nine model years of production.

There are two critical updates for the early 10-speed transmissions that should be installed if you are rebuilding one. The first and most well-known is the CDF drum. As the name implies, this drum is used for the C, D, and F clutches. Tightly integrating these three clutches allows the 10-speed transmissions to occupy roughly the same space as the 6-speed transmissions, simplifying fitment into existing vehicle platforms. The bushing in the original design drum can slide out of position over time, damaging the sealing rings that feed pressure to the clutches, causing slipping and erratic operation. Fortunately, there is an updated drum assembly that prevents this problem. This update was added to production transmissions in 2023.

The other common issue that occurs with high mileage is that the splines on the F clutch plates can dig into the aluminum outer shell or clutch container (often referred to as the "trash can" in YouTube videos). This will eventually cause the clutch plates to hang up in the shell splines, leading to F clutch failure. The updated shell is hard anodized and is black in color. Hard anodizing is a process commonly used for aircraft parts to provide a thin, but very hard wear layer on aluminum parts, so this recent update should eliminate this problem. Please also note that firmer shifts are more likely to wear the shell. Since the updated shell is black, and the shell is visible with the valve body removed, it is easy to check for this update without completely disassembling the transmission. With these updates installed, the 10-speed transmissions will be just as durable as the earlier four-speed units, while delivering unmatched levels of performance.

Online Criticism Versus Facts

If you follow commentary on the internet, you may have seen people express opinions that these transmissions are extremely complicated, have too many pieces to break and wear out, and are not reliable. While there were early challenges, most of them are related to factory software, or they have been resolved. The current GM recall regarding premature wear of the feed limit low valve has been addressed by the aftermarket, with two different companies offering solutions. We have addressed this issue in a recent video on the US Shift YouTube channel.

The complaints about complexity and reliability seem to be based on speculation and fear, rather than facts or experience. The use of modern clutch-to-clutch electronic controls greatly simplifies modern transmissions, compared to earlier units with simpler controls, such as the 4-speed units listed in the chart below. Items such as one-way clutches and redundant friction elements are eliminated, reducing parts count and failure points, while greatly improving shift quality. Also, the architecture of the 10-speed transmissions is highly optimized, further reducing component counts.

Clutches, bands, and one-way clutches (roller, sprag or mechanical diode) are the most likely components to fail in a transmission. As you can see in the chart, the 6 and 10 speed transmissions have some of the lowest clutch counts (no bands), and the lowest one-way clutch count (one). The only component that the 10-speed has the most of is planetary gear sets, with 4. When considering that many 4-speed transmissions have 3 gearsets, adding one more does not seem unreasonable to achieve six more gears. Gearsets are also less likely to fail than clutches, bands, or one-way clutches.

Also, please note that the unique parts count of the 10-speed transmissions is also lower than many of the 4-speed units (correlating with the major component counts). The unique parts counts are derived from exploded diagrams in factory manuals, and these numbers can vary due to different variants of the transmission and other factors. We have attempted to be consistent with the count methodology across transmission types, but these numbers are not exact.

| COMPONENT COUNTS | |||||

|---|---|---|---|---|---|

| Transmission | Friction Elements | Planetary Sets | One-Way Clutches | Unique Parts | Notes |

| 10R80 / 10L90 | 6 Clutches | 4 | 1 | 182 | Engine braking in all gears in drive. All synchronous, except 2-3/3-2 w/o eng braking. |

| 6R80 / 6L80E | 5 Clutches | 2* | 1 | 152 (6R) | Engine braking in all gears in drive. All synchronous, except 1-2/2-1 w/o engine braking. |

| E4OD | 7 (6 Clutches + 1 Band) |

3 | 3 | 196 | All shifts non-synchronous. Only 3 & 4 have engine braking in drive. |

| 4R70W / AODE | 6 (4 Clutches + 2 Bands) |

1* | 2 | 162 | 3-4 / 4-3 shifts are synchronous with heavy bind. Only 3 & 4 have engine braking in drive. |

| 4L80E | 7 (5 Clutches + 2 Bands) |

3 | 3 | 222 | All shifts non-synchronous. Only 3 & 4 have engine braking in drive ranges. |

| 4L60E / 700R4 | 6 (5 Clutches + 1 Band) |

2 | 2 | 196 | 2-3 / 3-2 shifts are synchronous. Only 3 & 4 have engine braking in drive ranges. |

* One of these are a compound planetary gear set, also known as the Ravigneaux gear set, named after its inventor, Pol Ravigneaux.

When considering this data, it is obvious that the 10-speed transmissions are not excessively complicated and that the reliability is comparable to earlier transmissions or better, especially when considering more recent or updated units.

Conclusion

Knowing all of this, we feel that a 10L80, 10L90, or 10R80 swap is one of the best “bang for the buck" options that you can add to your vehicle build. Its optimization of your engine’s potential leads to better performance than would be possible with any other transmission. The improvements in responsiveness, drivability, shift quality, and economy are extra bonuses that you will enjoy for years to come.

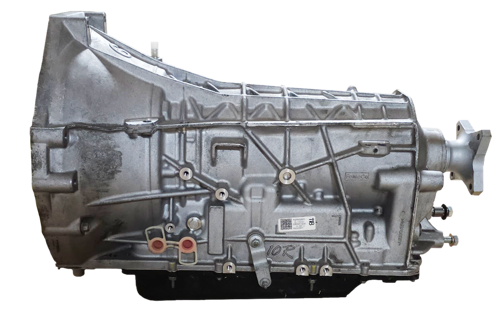

The 10R80 Transmission

A collection of important information all about the Ford 10R80, 10R100, & 10R60 transmissions.

Quick 10 Clutch-to-Clutch Transmission Control System

Control system for 10-Speed transmissions.